JLC is a technology driven company developing high-performance materials for especially demanding applications and processes. JLC has a modern and efficient specialty wire manufacturing facility which is fully integrated from the melting to the packing stage.

Our products find application in welding industry, electrical & electronics industries, automotive industry, energy & environmental technology, lighting, instrumentation, and other specialized applications. This creates a unique position for JLC as a one-stop-shop for materials in the niche filed of Nickel alloys

With more than 40 years of technical know-how, JLC endeavors for continuous technological upgrades for equipment and processes; the purpose of which is to optimize all our internal operations. This benefits our customers with even more reliable and cost competitive deliveries.

The quality management system adopted and certified by ISO 9001:2015 standard along with our commitment to Clean Work Environment – Lean Process – Support Green form the base for every technological innovation we seek.

JLC is a Technology Driven Company with an In-house R&D Center Developing High-performance Materials for Demanding Applications and Processes.

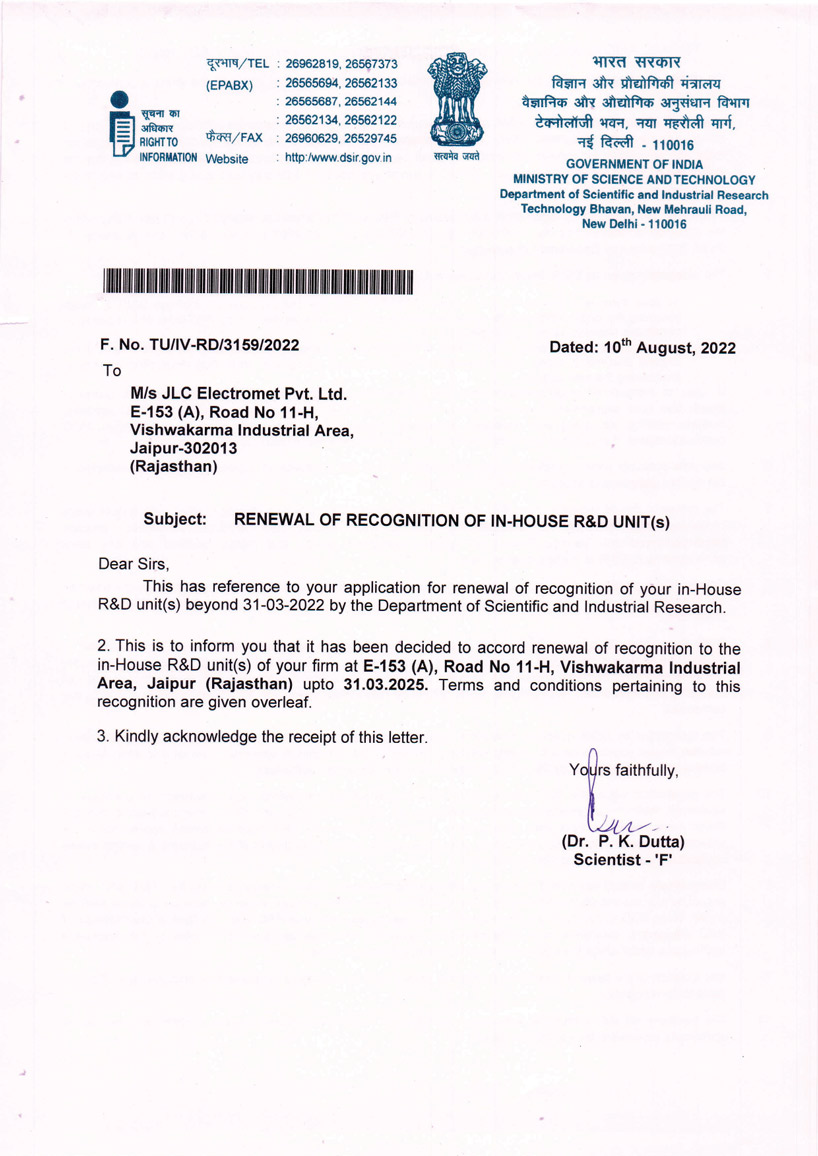

In-house R&D Centre

JLC has an in-house Research & Cevelopment Center accredited by the Department of Scientific and Industrial Research, Ministry of Science and Technology, Government of India in year 2010. The main objectives and goals of this department are:

- Continuous experimentation to develop new materials of high quality and low cost.

- Development of alloy variants within specified standards for special applications.

- Innovations to reduce process wastage to support our core value of Clean Work Environment – Lean Process – Support Green.

- Work to develop new methods of material testing and analysis.

- Training of operators, supervisors, technical team members and other maintenance support personnel to enhance personnel and overall shop floor skill standards.

Data collection through Statistical Process Control tools and online data loggers creates an extensive knowledge data base for the R&D team to work out process optimization solutions. In many cases, the unique and specific problems which our customers present inspire new developments and provide the foundation for innovative solutions.

Metallurgical properties of the alloys under development are carefully reviewed. JLC houses a large library of metallurgical books, technical handbooks, and journals. Engineering staff members regularly utilize these resources for problem solving and to keep themselves updated.

Accolades for Research Papers

JLC R&D team has also received recognition on international platforms for their research.

- 2004: Silver Certificate Award for Best Paper in Non-Ferrous Category by Wire Association International in USA

-

2004: Marshall V. Yokelson Award for Best Paper in Non-Ferrous Category by Wire Association International in USA

-

2006: Silver Certificate Award for Best Paper in Non-Ferrous Category by Wire Association International in USA

Customer Cooperation

Over the years, JLC has been involved in joint technical projects with its customers. JLC received the Global Supplier Award Breakthrough in 2007 from Royal Philips Electronics, Netherlands for joint development of Nickel-plated Dumet wire for Automotive Lighting in 2007-08

We are continuously working to sustain and strengthen our position as a technical and development partner for industry players.